What are the types and characteristics of balancers? How to choose and what are checkpoints? You can also find examples of installation.

We hear people say, “We are interested in balancers, but we are not sure what are the differences between balancers and other hoisting machines.”

In this article, we will introduce,

・Basic structure and roles of balancers

・Types of balancers

・Differences from other lifting devices

We also introduce some examples of the actual installation of our Intelligent Air Balancers

We hope this will give you some ideas for installation.

Basic Structure of Balancers

It might be easier to understand the principle of a balancers by comparing it to a balance scale. In a balance scale, a weight of known weight and an object to be measured are placed on the left and right plates, and the weight and number of weights are adjusted until the balance is level.

The balancers equalizes the force in the winding direction generated by springs (spiral springs), air cylinders, electric motors, etc., and the suspended workpiece (load), which makes the weight of the workpiece close to zero.

Benefits of Balancers

A balancers allows the operator to easily adjust the height of hanging tools or heavy items with little or no vertical force. Therefore, it makes aligning operation of tools and assembled parts easier, reduces the physical burden on the operator, and improves operability.

By installing balancers

- Workload saving for workers

- Labor saving from 2 to 1 worker

In this way, work can be done efficiently.

By reviewing the layout when installing balancers, you can expect to improve work efficiency even further.

Not only that, but also

- Prevention of accidents and injuries caused by falling heavy objects

- Prevention of back pain from working long hours

It helps to ensure the safety of employees.

Regardless of the worker's gender, age, or strength, they can work

- Same burden

- Same operation

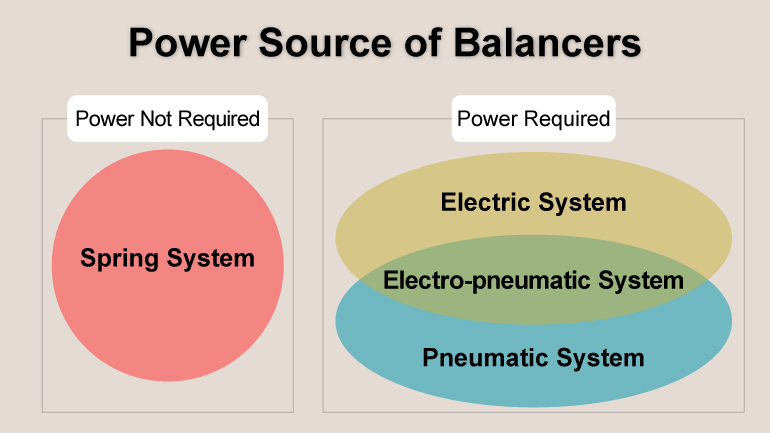

About the Balancers Power Source

There are various types of balancers power sources.

1.Spring type that requires no external power

2.Electric or air type using external power

3.Hybrid type(Electro-pnuematic) that uses air as the power source to achieve the balancing function through electronic control.

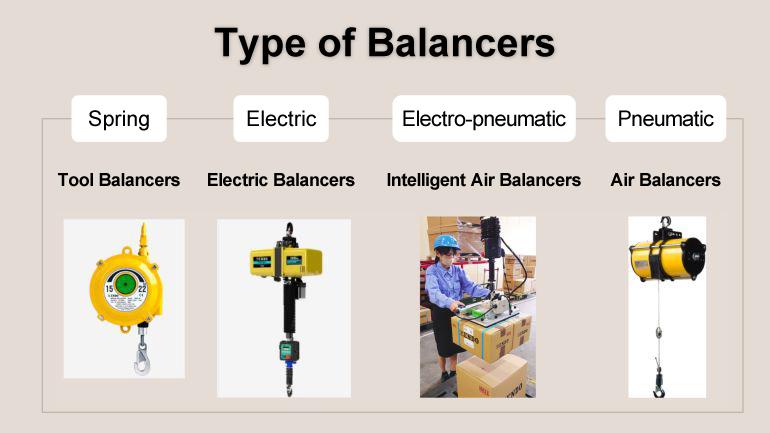

Product Name:Tool balancers

Power : Coil spring (spring)

Feature : Work can be performed with a small load by suspending and balancing tools, etc.

※*Cannot be used for transporting workpiece.

Product Name:Electric Balancers

Power : Electric (servo motor)

Feature : Rated load is 300kg. Balancing operation is possible. Fine aligning by servo control. Enable to follow the load fluctuation of the suspended load.

Product Name:Air Balancers

Power : Compressed air

Feature : The power source is air. Balanced operation is possible with a control module.It is used for conveying. It is suitable at sites where the use of electricity is restricted.

Product Name: Intelligent Air Balancers

Power : Compressed air (power) + electronic control

Feature : Power source is air. Rated load up to 130 kg. Smoother operation than air balancers by electric control. Balancing operation is possible.

We can make proposals to meet your needs and environment of use.

We can make proposals to meet your needs and environment of use.

Conveying Operations Using Balancers

We sometimes hear a question, ”Can we use a tool balancers to convey items?”

Because of the following two reasons,it is impossible to use tool balancers to convey items.

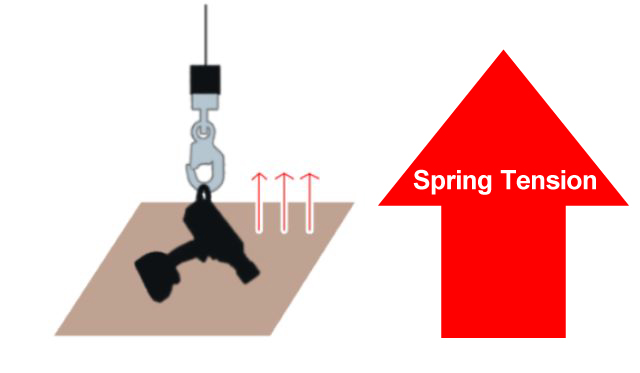

① Workpiece suspended by tool balancers cannot land on the ground.

Tool balancers always has a pulling force in the winding direction. Therefore, the suspended workpiece cannot land on the ground. It is always balanced (floating).

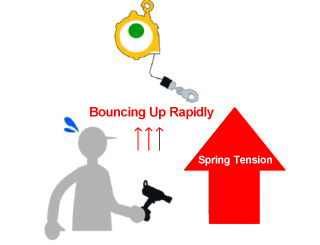

② It is very dangerous and difficult to attach and detach workpieces suspended by tool balancers.

When a workpiece is removed from the tool balancers forcibly, the tension of the spring causes the bottom hook to rise rapidly, and the wire rope is rapidly wound up into the case.

This is very dangerous because the wire rope and hook may hit the operator during the winding process.

Please use the drum lock when attaching and detaching workpieces. For models without a drum lock, store all wire ropes inside the case before attaching and detaching workpieces. When attaching and detaching workpieces, please do safely while reading the instruction manual.

Tool balancers are used with tools and workpieces left suspended.

On the other hand, the electric type or air-electric hybrid type balancers detects the load of the workpiece through control. And it automatically adjusts the force generated in the lifting direction to equalize with the load of the workpiece.

Thus, the workpiece can be removed. And so this type of balancers can be used for conveying items at plants or distribution sites, chucking into machine tools, and conveying molds.

Tool balancers

Tool balancers is used to keep suspending loads.

- Various tools

- Various equipment

Unhooking a load while the spring is under tension may cause the wire to jump It is dangerous. This product cannot be used for work that requires the removal of a suspended load, such as conveyance work. This product cannot be used for work that requires the removal of a suspended load, such as conveyance work.。

No external power such as electricity or air is required.

Because the structure is so simple, it is easy equipment to install.

| Purpose |

|

| Advantages |

|

② Electric Balancers

Electric Balancers is load handling equipment with balancing function for lifting heavy loads with electric power.

It makes it possible to manipulate heavy loads with less force at the balancing operation.

| Purpose |

|

| Advantages |

|

Air Balancers

Air Balancers is load handling equipment that is mainly powered by compressed air. It can be used without electricity. The piston structure of the Air Balancers gives a light and airy feel. Continuous operation is possible because it is powered by air.

| Purpose |

|

| Advantages |

|

④ Intelligent Air Balancers

Intelligent Air Balancers is a new generation air balancers combining compressed air and electronic control.

Smooth changeover from gripping to balancing operation without any switch operation.

| Purpose |

|

| Advantages |

|

What are the differences between balancers and other assistive devices?

“We understand that balancers reduce the burden on the operator, but what kind of assistive device exist in the first place?”

You may be interested in other types of assistive device.

The most important thing is to choose assistive device that suits your work environment.

Let’s consider installing a balancers while understanding how it is different from other assistive device.

Air Hoist

The air hoist is powered by compressed air and operated by a push-button system. The speed can be adjusted by pushing the button, and it can be operated flexibly from high to low speed. Less chance of ignition compared to electric systems because of air power, therefore, the hoist can be used in the locations as follows:

- Chemical plants.

- Locations where hazardous materials are handled.

<Advantages>

- Compact and lightweight design.

- Suitable for work requiring speed.

- High safety because the power source is air.

<Disadvantages>

- No balance function because of no load detection.

Assistive Suit

Assistive suits are supporting devices that people directly wear and use.

It reduces the burden of heavy loads on the body and protects the back.

<Advantages>

- Makes it easier for women or the elderly with limited strength to work.

- Can be used in limited spaces where only one person can enter.

- Can be moved easily.

- Using assistive suits makes workers feel easy to work.

<Disadvantages>

- Relatively small weight capacity.

- Not a full body aid.

Specific Examples of Installation◆Intelligent Air Balancers

Here are some installation examples of our Intelligent Air Balancers.

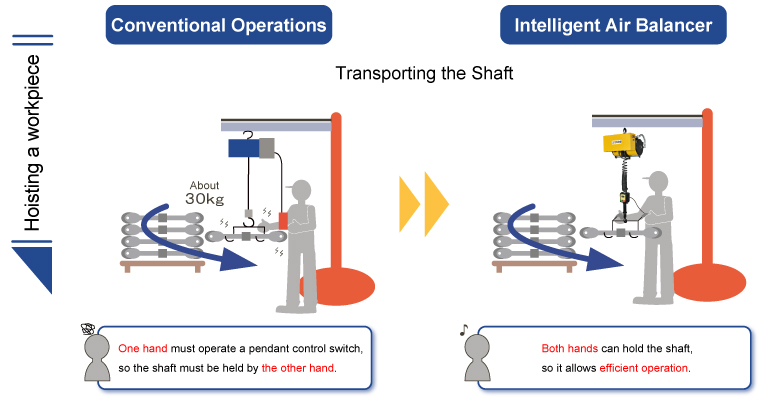

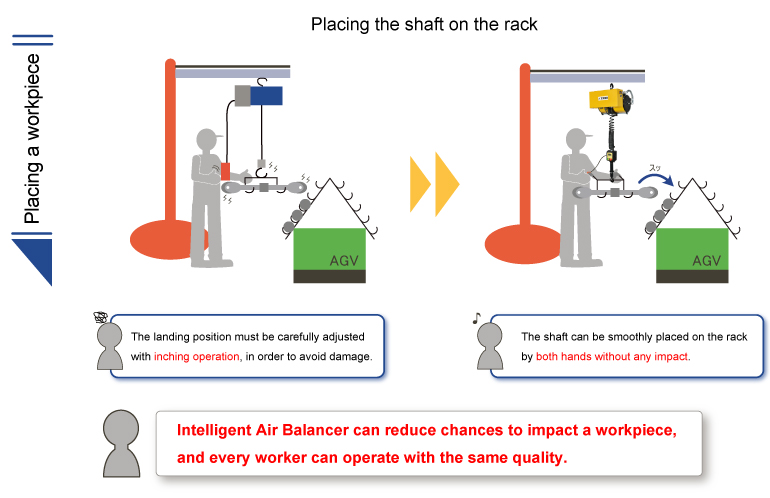

①Automobile parts plant

The challenge was how to convey workpieces quickly and accurately without damaging them.

<Tasks>

1、Lift workpieces

2、Land workpieces

The installation of balancers reduces the risk of impact to workpieces.

Inching is not required, therefore, even unfamiliar operators can work with the same quality.

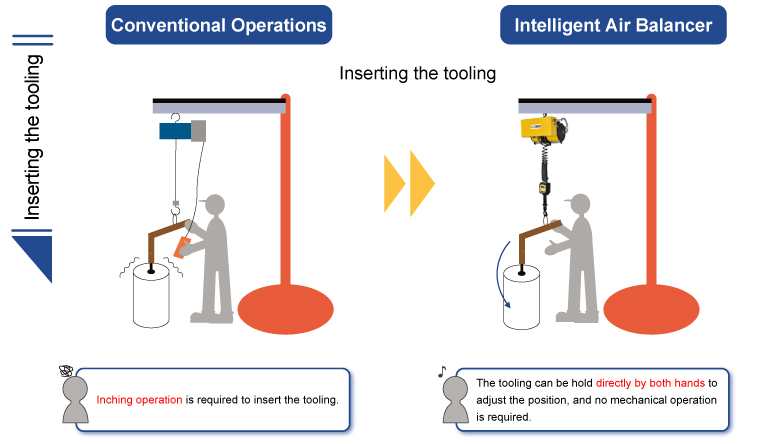

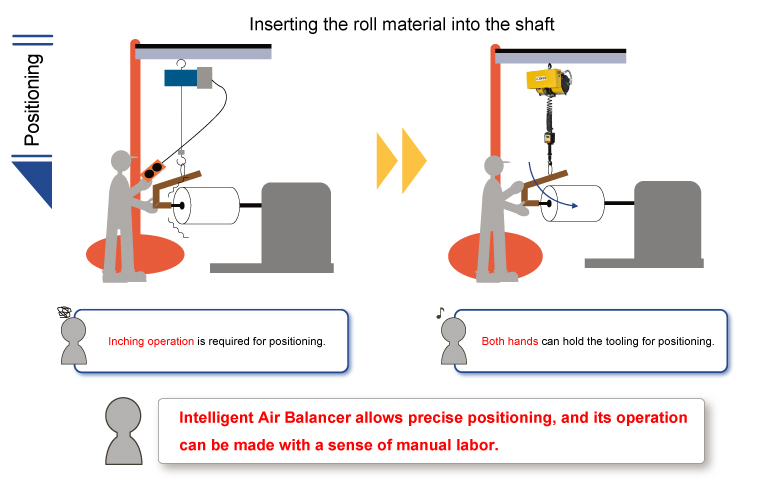

②Conveyance of Rolled Materials

<Tasks>

1、Attach jig

2、Align the position

Fine- tuning has become easier with the support of Intelligent Air Balancers for aligning. Work efficiency has been greatly improved because work can be done smoothly as if it were done by hand.

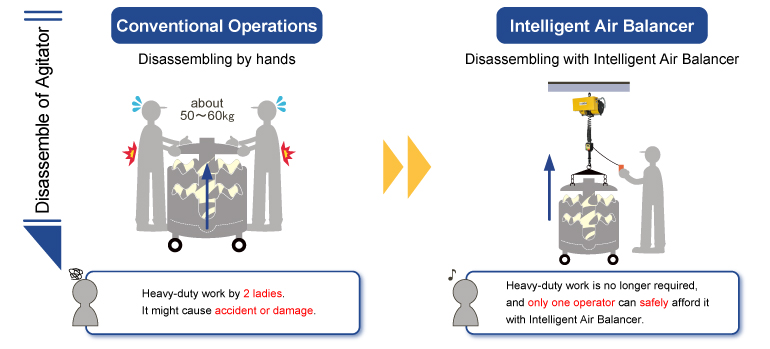

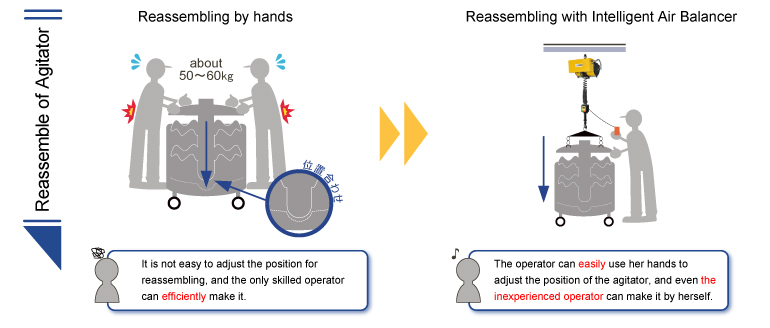

③Food Plant

Assistive devices were being considered to enable anyone to work alone.

<Tasks>

1、Disassemble the agitator

2、Clean the agitator

3、Assemble the agitator

Even difficult tasks such as supporting heavy items can be performed safely. The operator's workload is greatly reduced and operation is simple, so that any operator can work alone.

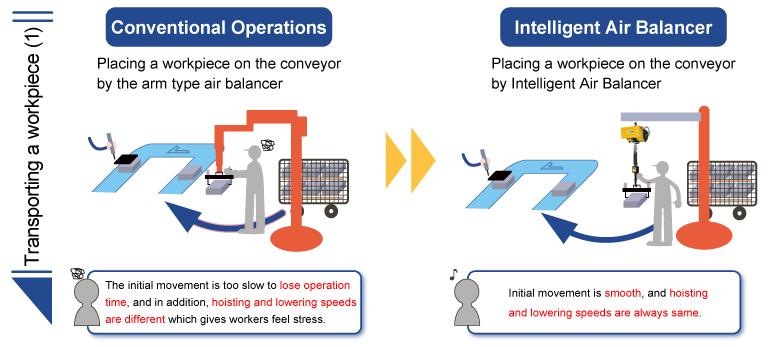

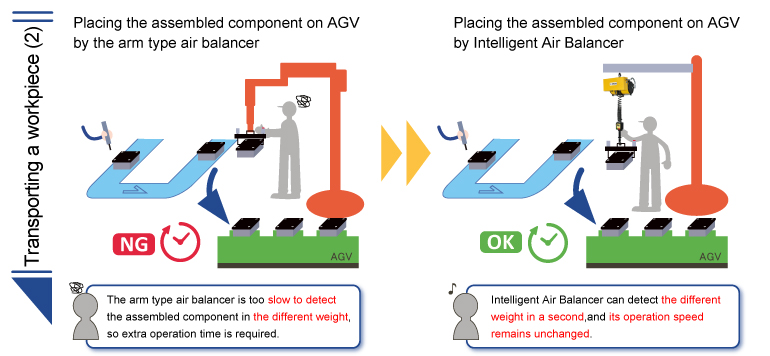

④Assembly Plant for Engine Parts

In order to improve conveying operations and shorten takt time, a company was considering installing a balancers.

<Tasks>

1、Convey workpieces

2、Assemble

3、Convey workpieces

Time-consuming processes due to difficult-to-handle equipment have been improved. Tact time has been successfully reduced, and the stress of operators, whose sense of operation changes each time, has been eliminated.

What to Check Before Installing a Balancers

「Let's install a balancers.」

Even if you decide to install a balancers, it may not be possible to do so depending on the environment of the site.

We recommend that you first confirm in advance whether the environment is suitable for a balancers.

1、Is There Enough Space for the Equipment?

Please check the area for the equipment in advance.

- What floor is the equipment installed on?

- How high is the ceiling of the location?

- What is the floor load capacity at the location where installation is considered?

Please confirm that there is enough space to install a balancers.

If a balancers is installed on a jib crane and used by turning, please make sure that no objects will hit it within the turning radius.

2、Is There Enough Space to Work?

You will need to consider the workspace along with the installation.

Workspace requirements vary, so it is important to know how much space you will need.

3、Fixed or Mobile?

There are two kinds of balancers.

・Fixed type (Floor or Ceiling)

・Mobile type

In the case of fixed balancers, as many balancers as the number of operations to be covered are required.

4、What Kind of Items to Convey

- Shape

- Physical properties

- Weight

Depending on these factors, attachments will be different.

If there are multiple types of workpieces to convey, the workpiece information must be confirmed in advance.

5、What is the Capacity of the Load?

Depending on the workpiece conditions, load capacity is different.

- Consider the appropriate attachment for the target workpiece.

- What is the load capacity?

These are important points to check when installing equipment.

Not Sure Whether to Use Assistive Device or an Industrial Robot.【Five challenges to clear】

For those who are still wondering whether to choose assistive device or an industrial robot.

Industrial robots perform assembly and other work in factories instead of humans.

Although they are very convenient, there are five challenges to install industrial robots.

| Initial cost | Large initial cost to install. |

| Losses due to defects | If a defect occurs in the installed robot, the following may happen.

|

| Requires certification for operation and inspection | Industrial robots, with the exception of some robots, require the following qualifications.

|

| Risk of injury due to misoperation |

|

| Secure installation space | Some products are large in size and require additional work space. |

You need to understand these challenges.

Summary

Types of balancers include:

- Tool balancers

- Electric balancers

- Air balancers

Tool balancers are used with the suspended load left hanging.

- Various tools

- Various equipment

Balancing these things in the air allows you to work with light force and precision.

Electric balancers and air balancers are used for heavyweight items

- Lifting

- Conveying

They support weight and provide mobility assistance when working.

It is also called an aid or weight-assist equipment because it reduces the workload.

By installing a balancers, you can

- Prevent injuries caused by falling heavy objects

- Prevent back pain due to work

- Save labor of operators

- Reduce the number of workers from two to one

We hope that these actual examples and points to check for installation will help you consider installing a balancers.