Magical Balancer

We would highly recommend the "Magical balancer" to companies that are having trouble transporting heavy objects.

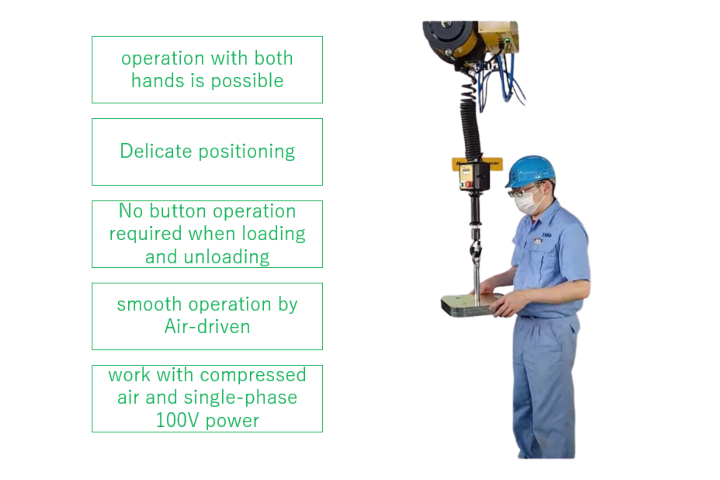

The operation is simple and does not require any complicated steps.

It is ideal for sites where transportation and assembly work involving alignment is carried out.

A 100V single-phase power supply and compressed air are required.

■Main Applications

・Transporting heavy items carried manually

・Attaching the workpiece to the chuck of the processing machine

・Positioning during assembly work

・Handling heavy objects that require delicate work

Movie of Magical Balancer: Everything You Need to Know in 2 min!

No Button Operation is Required Automatically to Switch to Float Mode

Key Safety Features

Catalog・CAD・Manual Download

Features / Specification / Application

Inquiry

Movie of Magical Balancer: Everything You Need to Know in 2 min!

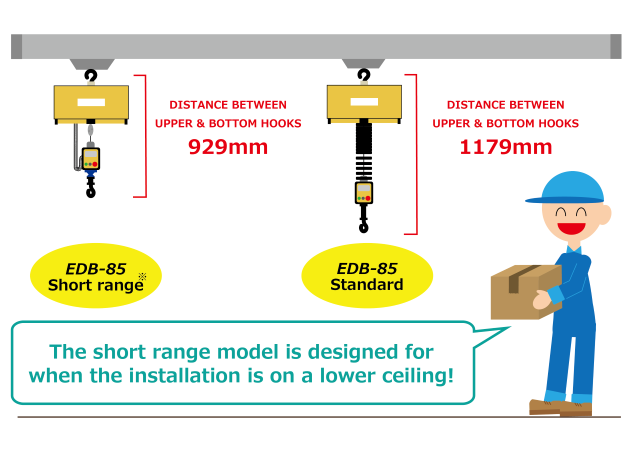

Low Ceilings are not a problem! Magical Balancer (Short Range Model)

・Either model of the different ranges can be selected according to a working space to meet the operation range.

・It allows smooth operation that can be combined with a rail system or a jib crane.

・The short range model of Magical Balancer is the special specification.

Please contact us for further information on the inquiry form.

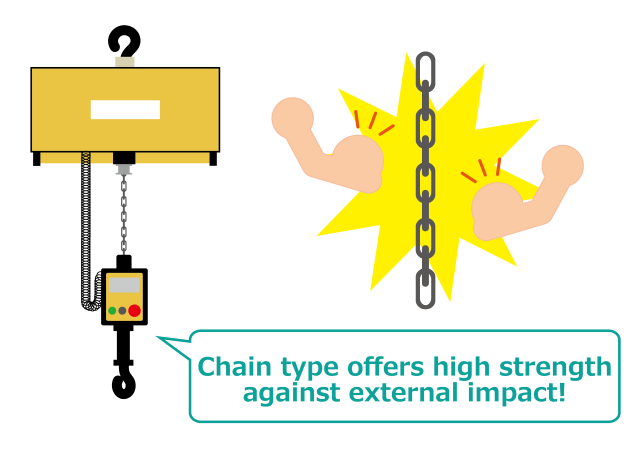

Chain Type Offers Higher Durability to External Impact

・The standard model comes equipped with a wire rope but can be changed to the chain type for increased strength and impact durability.

・Due to assembly processes, the length of the chain is set to within ±50mm of the standard length. Please contact us for further information.

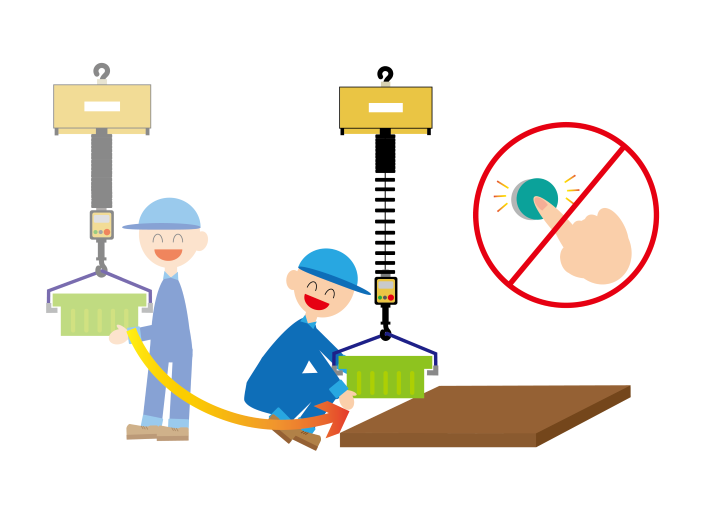

No Button Operation is Required Automatically to Switch to Float Mode

・You do not have to do a bothersome button operation whenever hoisting and lowering a workpiece after the load weight is detected.

Key Safety Features

■What happens if the suspended workpiece suddenly falls??

→Snap back arrest safety feature is equipped to prevent injuries caused by bouncing

■What happens during a power outage?

→Magical Balancer will not drop the load even if the air supply and electrical connections are disconnected.

This video shows the entire process until the load is lowered by pressing the emergency descent button.

Download

When you lift the load, the weight of the load is automatically detected. After lifting up, you can move the suspended load by using your hand to your desired position. Anyone can do this operation very easily. Lifting speed is almost same for different weight load.

Realizing smooth operability by adopting a new control method that combines electronic control and air control

- By equipping sensor on the grip, the weight of the suspended load is detected in real time and air pressure in the cylinder is automatically controlled. It realizes smooth and light operability, quick operation and followability.

Grip operation mode that shorten the required time to lift off the ground

- This mode is used to attach / detach the suspended load and lift up / down the suspended load by sliding up or down the grip.

- By detecting the weight of the suspended load in real time, the required time to lift off the ground has been significantly reduced (* patent pending).

Work balance mode that reduces the operating force

- By sensing the force added to the suspended load, the operating force in balance mode is greatly improved.

- When you release the grip, it instantly shifts to work balance mode.

- Compared to our standard air balancers , The balance operation force (operating force) in the work balance mode has been reduced to about 1/2 to 1/3 (* patent pending)

Function for allowing gradual weight change of the suspended load

- Cylinder pressure is automatically adjusted according to changes in the weight of the suspended load to maintain the suspended load.

-

[Application]

Pouring the liquid contained in the lifted container into another container. -

[Note]

It may be necessary to consider your work condition if you use this function. Please contact us for details if you want to use this function.

Improved maintainability

- By equipping an alarm function that displays the details of the error when an abnormality occurs. It reduces the time to spent to identify the cause of anomalies. For example, it can quickly detect an abnormality such as a drop in air pressure.

Specification

| Model | Air pressure (mpa) |

lifting capacity (kg) |

Travel (m) |

Mass (kg) |

Wire rope diameter (mm) |

Air Connection |

Electricty |

|---|---|---|---|---|---|---|---|

| EDB-50 | 0.4 | 20 | 1.9 | 42 | Φ4.76 | Rc 1/2 | AC100V-240V |

| 0.5 | 30 | ||||||

| 0.6 | 40 | ||||||

| 0.7 | 50 | ||||||

| EDB-85 | 0.4 | 40 | 1.9 | 43 | Φ4.76 | Rc 1/2 | AC100V-240V |

| 0.5 | 55 | ||||||

| 0.6 | 70 | ||||||

| 0.7 | 85 | ||||||

| EDB-130 | 0.4 | 61 | 1.9 | 50 | Φ4.76 | Rc 1/2 | AC100V-240V |

| 0.5 | 84 | ||||||

| 0.6 | 107 | ||||||

| 0.7 | 130 |

Magical balancer is a perfect choice when you need assistance with...

- Positioning in assembly shop

- Setting workpieces to machines

- Material handling with a jig

- Changing a mold etc.

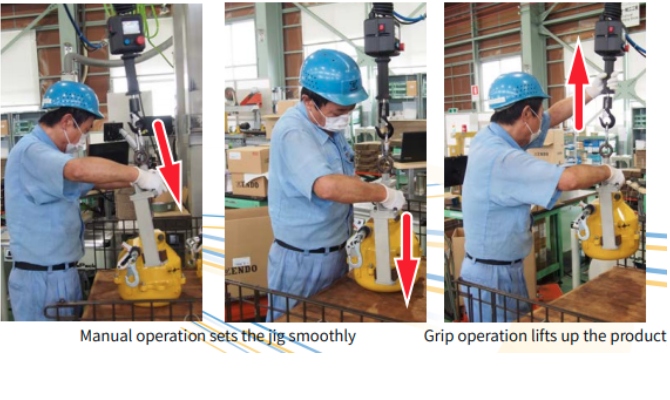

Application at our factory!

We try our Magical Balancer on our production line.

Product Handling

- Magical balancer assists carrying and packaging the product.

- The product is set into a frame in a package with Manual operation.

- The operation is performed with no shock and no damage to the product.

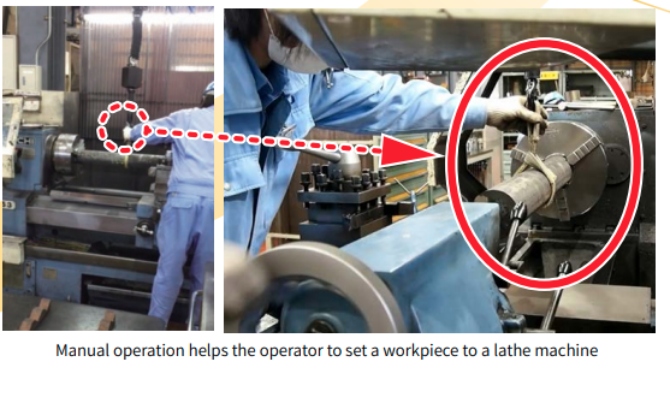

Setting a workpiece to a lathe machine

- Magical balancer supports precise adjustment.

- It eliminates the inching process and frees the operator from direct handling of heavy workpieces.

Accessories

Rail System

This system allows horizontal movement of lifting equipment, enabling easy transportation and transfer by hand.

Rail system detail page

Jib Crane

A floor-mounted jib crane is available as an accessory. The traveling rail is made of aluminum, enabling light and smooth operation.

Jib crane detail pageInquiry

Please wait for a moment until the form is displayed.

We apologize for the inconvenience, but if the form does not appear even after waiting for a while, please .contact us.